Home > Products & AFS > Planting & Seeding > 2000 Series Early Riser Planters

HIGH-EFFICIENCY PLANTING: COVER MORE GROUND IN LESS TIME

High-efficiency opens up your planting window

Maximize yield potential

High-efficiency planting

Customizable

Easy maintenance & adjustments

2160 Early Riser Large Front-fold Planter

Expanding the lineup of 2160 Early Riser® large front-fold planters with two new 60-foot configurations — the new 24-row 30-inch and 47-row 15-inch with split rows — delivers more capacity for large-scale producers:

Seamlessly collect and store high-definition planting data on an iPad with The Climate Corporation FieldView® Cab app.

Sixteen inches of vertical row unit travel improves performance in varied terrain while providing greater clearance for residue managers. Cast-iron row unit is built with larger, common hardware and fewer parts.

CleanSweep® air cylinders allow for in-cab adjustments of residue manager ride to accommodate soil and residue conditions.

Larger diameter and thicker Earth Metal® offset opener blades are agronomically designed to slice through residue and tough soil conditions.

Inverted closing disks zip the trench closed, placing high-moisture soil directly onto the seed. The press wheel ensures proper seed-to-soil contact.

Pulled gauge wheels with soil relief grooves eliminate sidewall compaction and control soil flow through changing ground speeds. The furrow-forming point creates the industry’s only flat-bottom seed trench.

Through up-or-down hydraulic pressure, automatic and row-by-row DeltaForce® achieves consistent weight on the gauge wheels for unparalleled depth control. Or select air downforce with or without in-cab gauge wheel feedback.

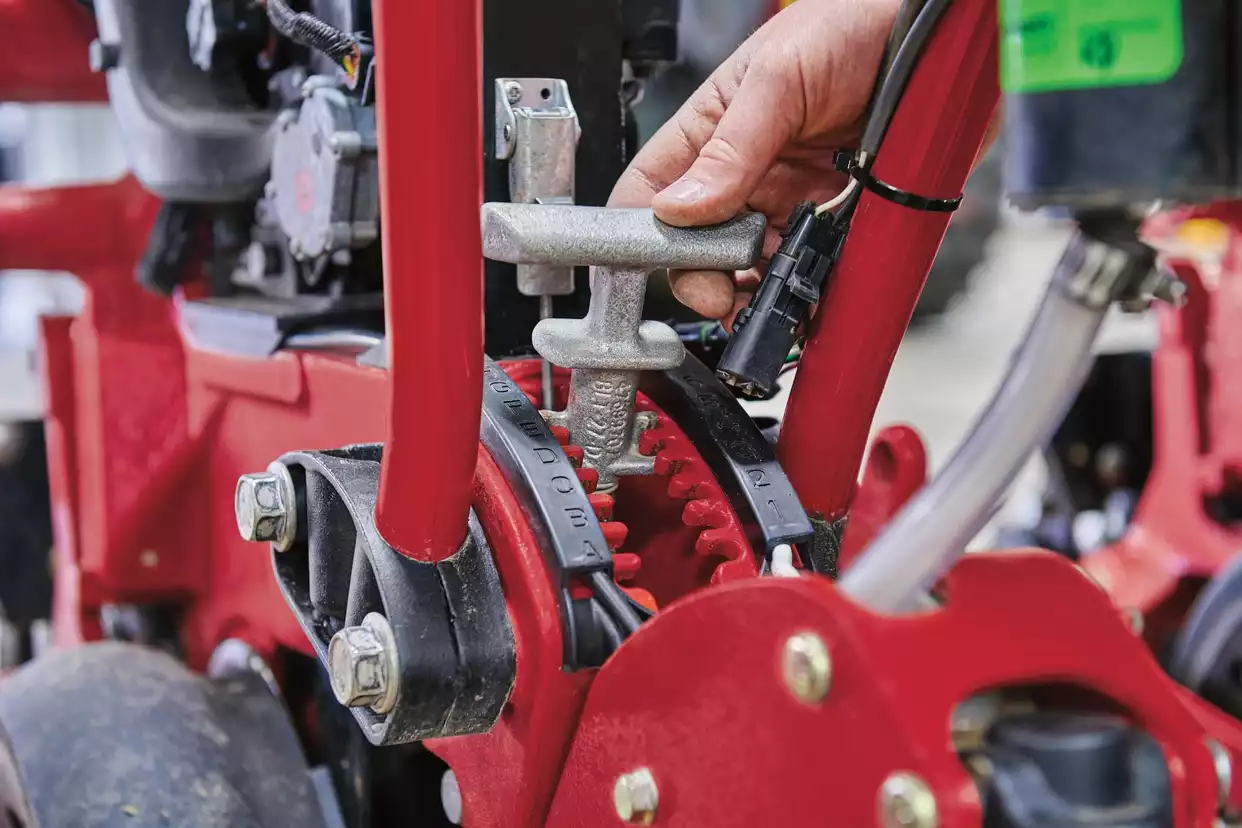

vSet® 2 Seed meter with vDrive® electric drive motor

Row-by-row overlap control and curve compensated spacing deliver optimal seed singulation and spacing. A simple design provides tool-free crop changes and reduces mechanical drive components.

For the most accurate seed delivery and placement to and in the trench, the 2000 series ASD option includes the new SpeedTube from Precision Planting. Available for corn and soybeans, the SpeedTube™ uses a flighted belt to control the delivery of the seed from the meter to the furrow, eliminating the drop and tumble variability of traditional gravity drop tubes, especially at high speeds.

Extend your planting window with the Rowtrac™ Carrier System. With increased flotation over a wheeled carrier, this carrier system reduces compaction and improves yield potential in wet spring conditions. Plus, it provides better maneuverability and a smoother toolbar ride.

The Rowtrac Carrier System is currently available as a factory-installed option for the 2160 Early Riser planter and will be available for the 2140 Early Riser planter for spring 2019. A conversion kit for the 2140 planter will also be offered for producers who desire to convert their planter to tracks.

Highlights of the steerable Rowtrac Carrier System include:

Exclusive towed-implement track undercarriage design is pivotable on three major axes for pitch, roll and yaw movement. This system allows the tracks to uniformly minimize ground pressure, even in rolling terrain.

Transport steering improves maneuverability, especially in tight field entrances.

One set of track paths controls in-field traffic and reduces pinch row compaction from dual wheels.

Fore-aft track oscillation provides excellent ground contact and weight distribution on undulating terrain.

Side camber promotes even wear and extended track life through uneven terrain and roading.

Fit the way you farm: as the only planter engineered and built with Precision Planting® components, you can customize your planter with the most accurate planting technology, direct from the factory. And, while others may offer some of these components, only the 2000 series Early Riser planter combines Precision Planting technology with the industry’s most agronomically designed row unit.

Easy service access & simplified adjustments: many components of our 2000 series Early Riser planters – including the metering system and row unit settings – provide tool-free crop changes and adjustments.

Plus, we’ve eliminated all the mechanical components – hex shafts, bearings, couplers, sprockets, chains and clutches – needed to turn a conventional planter. Fewer things to go wrong means reduced, simpler maintenance.

A 12-, 16, and 24-row planter with 30 inch spacing that requires anywhere from 180-500 engine hp based on planter size and desired speed.

Factory-integrated precision planting technology: as the only planter engineered and built with Precision Planting® components, you can customize your planter with the most accurate planting technology, direct from the factory. And, while others may offer some of these components, only the 2000 series Early Riser planter combines Precision Planting technology with the industry’s most agronomically designed row unit.

Choose between the total planter control and continuous feedback available through the Case IH Pro 700 display or FieldView® with the 20/20 SeedSense® options available from Precision Planting

Eliminates overlap with the all maintenance-free v-Drive electric meter drive system

Uses GPS to provide row unit shutoff capabilities

Allows you to adjust your planting rate from the cab using the Pro 700 control center

Immediate seed placement feedback to make corrections

Available for corn, popcorn, sugar beets and sunflower crops

Choose between the total planter control and continuous feedback available through the Case IH Pro 700 display or FieldView® with the 20/20 SeedSense® options available from Precision Planting

Discover the after-sales services available for your product.

© 2026 All Rights Reserved

Interested in one of our Case IH machines? Request a personalized quote and we’ll get back to you with all the details you need to power up your next project!