Home > Products & AFS > Harvesting > Harvestors Axial-Flow 250

Built for the challenges associated with high-yielding crops, climate change and the need to become ever more efficient, Case IH Axial-Flow® combines are changing the landscape of harvesting-technology yet again. With the latest features including AFS Harvest Command™ automated harvesting technology, the 250 Series meets the demands of large modern farms and contracting businesses: high-speed harvesting, increased threshing capability even under the most challenging conditions, and delivery of unbeatable grain quality. As inventor of the single Axial-Flow® rotor design on self-propelled combines, Case IH continuously innovates to maximise your productivity. Feeder, rotor, grain tank, unloading system and automatic adjustments are designed to handle large grain throughput and ease your harvest.

Case IH Advanced Farming Systems (AFS™) collect and deliver important data for your management decisions on crop cultivation and cost management.

Precision equals performance

By means of AFS AccuGuide GPS-controlled auto-steering, your combine is guided automatically – with a repeatable accuracy down to 2.5cm, track after track, to reduce overlaps and minimise time and fuel consumption during harvest. Precision farming technology reduces operator fatigue, boosts productivity and lets you exploit the combine’s full capabilities. With AFS Connect™, all your data are transferred to your farm computer in real-time, enabling you to provide instant advice and directions whenever you see the need to make immediate operating adjustments.

The Axial-Flow feeder has been designed for high performance, stability and easy handling. Equipped for the largest headers widths of up to 14 m and corn headers with up to 18 rows, the 250 Series combine offers two HD feeder options, extended with 15% and 35% higher lifting capacity.

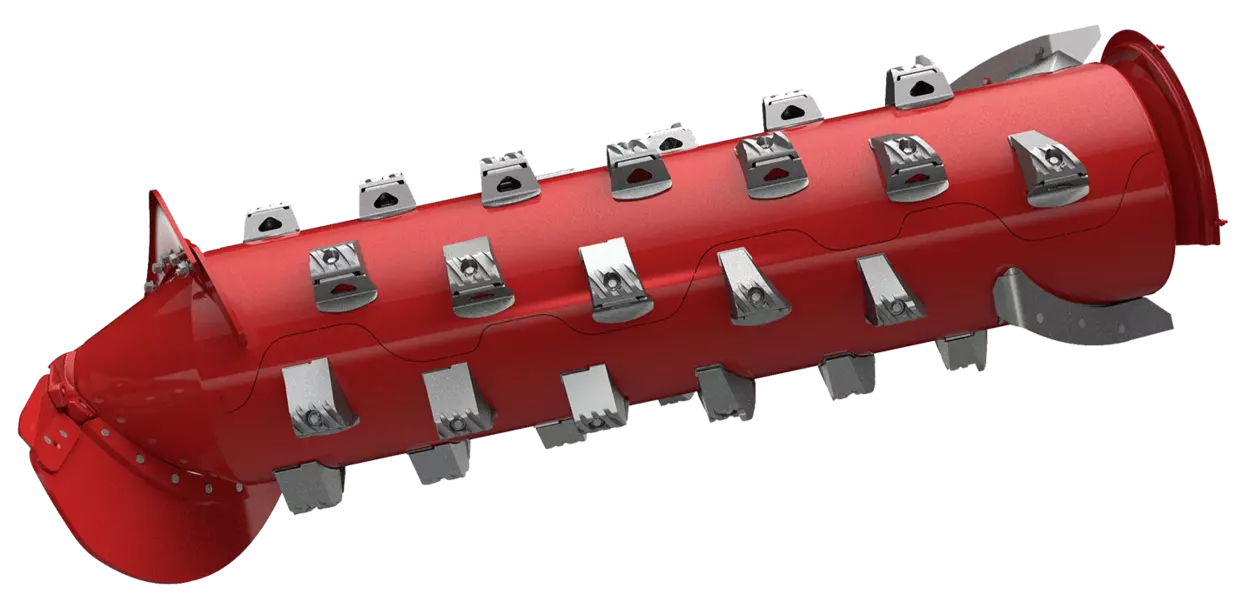

Combine throughtput begins here

The excellent lift height creates a ground clearance of 1.35m, aiding headland manoeuvrability and placing headers onto header trailers. While headers of up to 14 metres deliver massive volumes of material in high-yielding conditions, the feeder is fully up to the task. A wide and high feeder opening and stronger cast slats on the feeder chain, higher set slip clutches and an improved feeder transmission draw the crop in and feed it evenly into the rotor. Foreign material such as stones is pressed into a large stone trap by a rotating stone-catching drum, protected by a friction clutch against damage.

Whether it precedes conventional, min-till or no-till establishment, finely lacerated, evenly-spread straw provides the best start for the next crop, boosting breakdown and enhancing incorporation speed through natural processes.

Residue management – the start of the next crop

Choose from the integral chopper version or the Xtra-Chopping system to suit your requirements. The integral chopper is used for chopping or for transferring residue for when leaving unchopped swaths. Four different modes of operation are available: typical chopping mode, spreading long straw, and swathing with or without chaff. Straw from the rotor and chaff from the cleaning system are mixed and spread evenly during the spreading process, regardless of which system is used. And whichever mode is selected, it is a quick and simple process to switch from swathing to chopping, carried out from the operator’s seat via the AFS 700 Pro monitor.

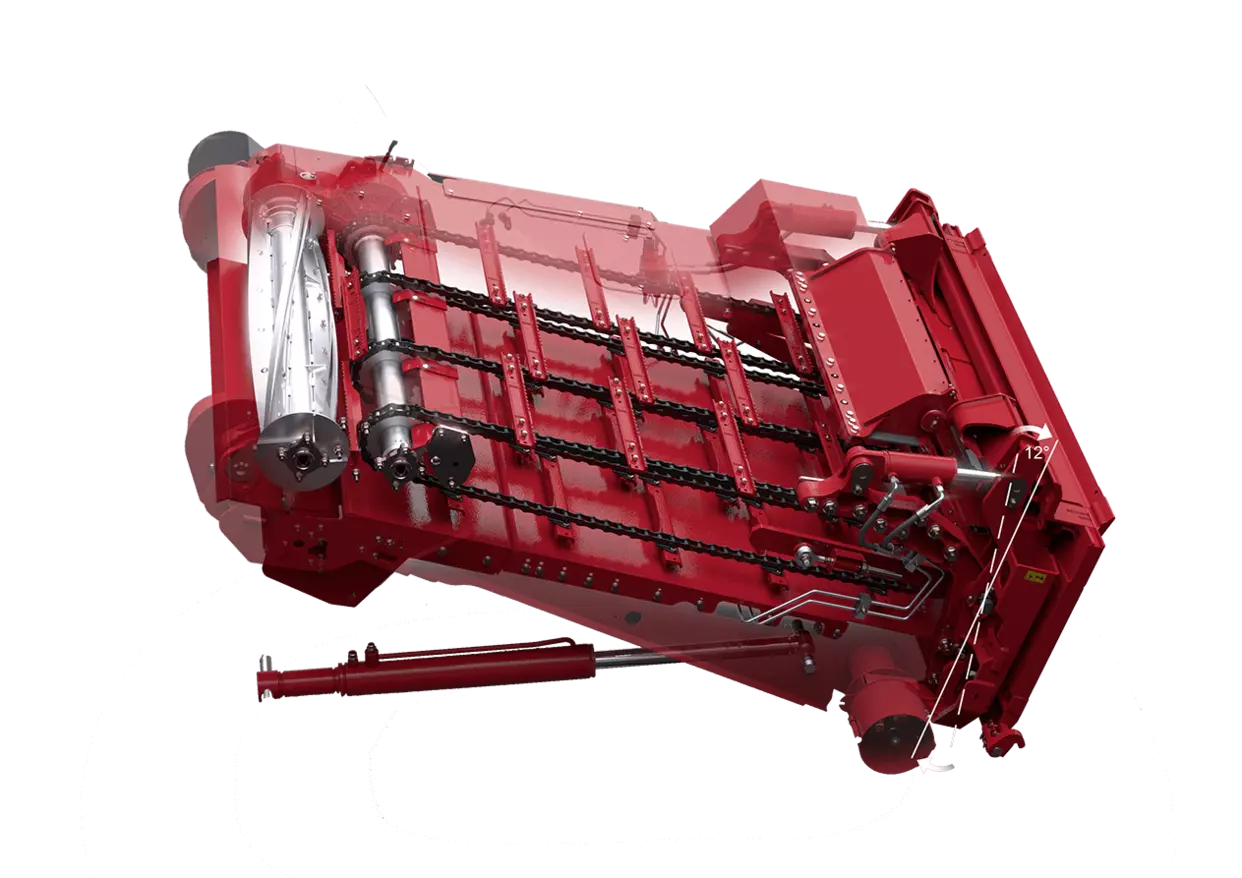

™The self-levelling cleaning system, plus adaptive cleaning fan speed that responds to the topography – controlled either by the operator or the Harvest Command™ option – is designed to help regardless of the conditions and field type and crop you are working in.

100% productivity

Part of the pre-cleaned grain is sent directly to the lower sieve, relieving the load on the upper sieve and resulting in an increase in cleaning performance while minimising grain losses. An inclination sensor initiates the levelling of the total cleaning system, which slopes up to 12% when working on side hills. This self-levelling sieve system allows use of the combine at full power and constantly high cleaning performance, regardless of gradient.

Grain tank capacity and unloading speed are key to output. With a 113 l/sec unloading rate, 250 Series Axial-Flow combines feature an unloading system of sufficient capacity to empty the grain tank within two minutes.

Quick, smart and efficient grain handling

The 8250 and 9250 models feature a larger than ever grain tank with an astounding 14,400 litres capacity. The optional high capacity (HC) discharge system empties at a rate of 141 l/s on the 7250 or 159 l/s on the 8250 and 9250, reducing unloading times in high-yielding crops, whether on the move or on the headland, boosting both combine and grain haulage productivity. The unloading auger is of a sufficient length to allow for a comfortable distance between the grain trailer and the combine when unloading on the move, and is suitable for 12m controlled traffic systems.

Capable of harvesting over 130 different crops via quick and easy adjustments, Axial-Flow combines are among the most advanced machines on the market. Thanks to the single rotor Axial-Flow design, Case IH combines consistently deliver best grain quality and minimal grain loss.

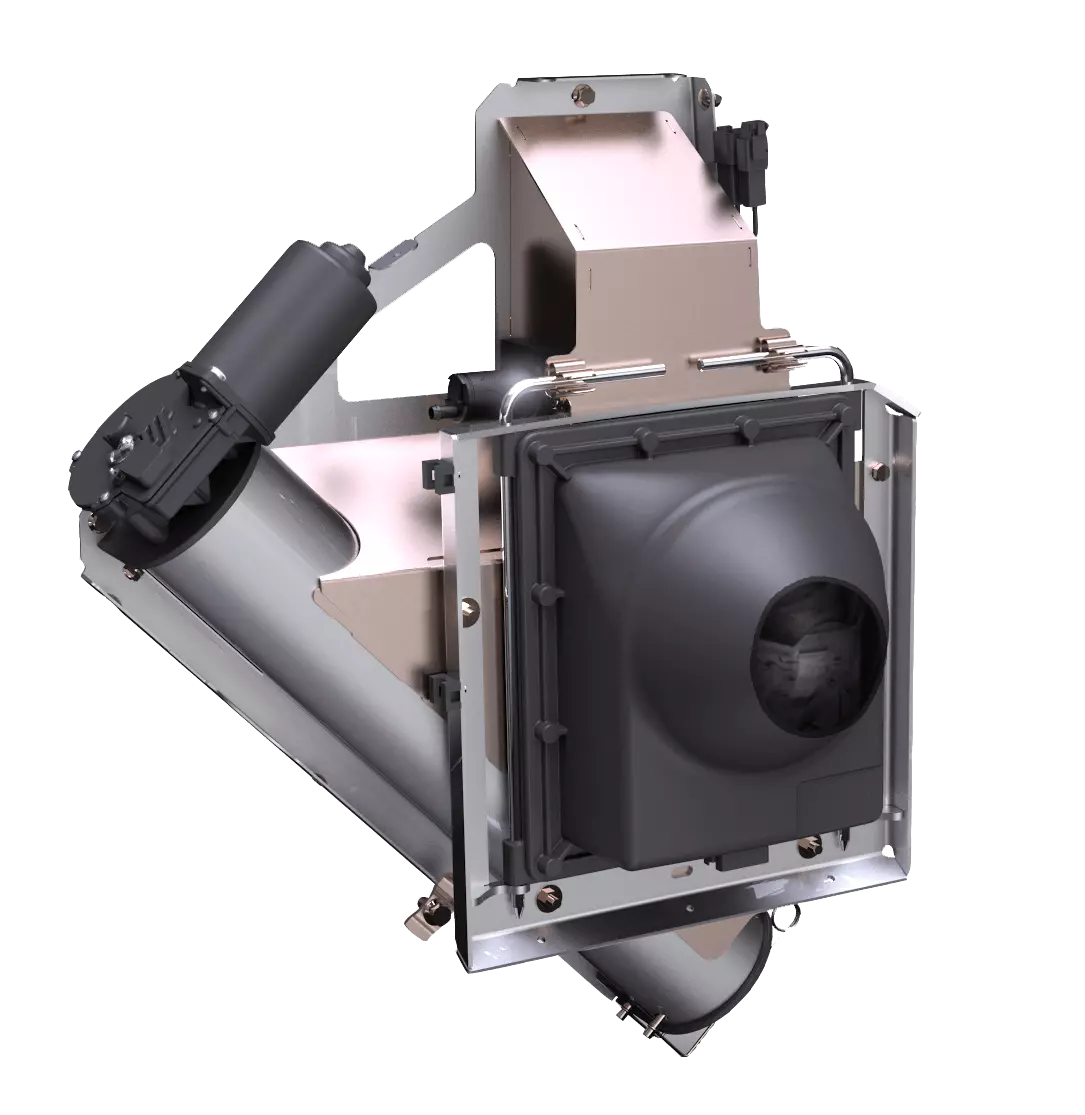

Unbeatable grain quality

With the AFS Harvest Command™ option, the new 250 Series feature the latest harvesting technology, with auto-adjust sieves and auto-adjust cleaning fan to obtain the cleanest undamaged grain sample with minimal losses. An optional rain quality camera is available to form the heart of the full AFS Harvest Command™ system, assessing levels of non-grain material and broken grains, and working fully automatically and in real time to adjust settings in response.

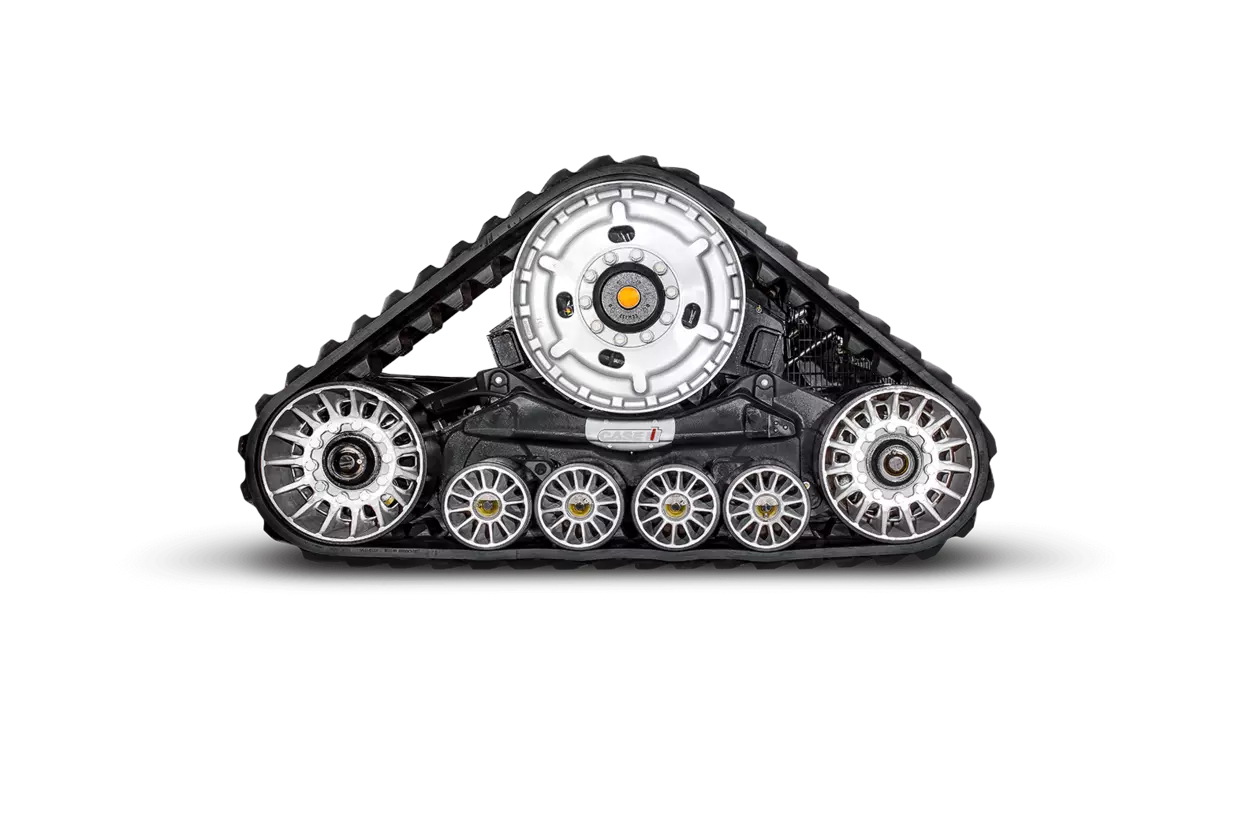

Modern tyre technology allows for a combination of high travel speeds on the road and low ground pressure to protect soils in the field. Axial-Flow® combines can be fitted with anything from VF710/70 R42 tyres for transport widths below 3.5m to IF900/60R32 for flotation on softer soils.

Increased traction with low ground pressure

With a front track option it’s possible to boost traction and flotation for effective soil protection on sensitive soils, whilst ensuring a transport width of just 3.5m on 610mm tracks. The hydrostatic ground drive features a variable speed motor option which enhances traction and hill-climbing ability for consistent ground speed. The new two-speed transmission with hydraulic high/low switch provides ample traction to handle difficult conditions. Depending on your requirements with regard to drive comfort and ground pressure, you can choose between rubber-damped or suspended track options.

Our engineers have created one of the quietest, most spacious and most comfortable cabs on the market, designed for long and profitable days. The Axial-Flow 250 Series has been designed with easy-access and sturdy steps.

Work comfortably from dawn till dusk

Behind the cab door you will find ample space and storage, with excellent comfort, further enhanced by an ergonomic layout, air suspended operator seat, low noise levels and unrestricted views. When harvest extends late into the night, stadium lights are fitted to the Axial-Flow 250 series roof to illuminate your work area. For full control, the essential functions are integrated into the right-hand console and the multi function control lever. The most commonly-used features and the AFS Pro 700 monitor are close at hand and ergonomically laid-out.

Discover SAFEGUARD CONNECT: the combination of the best Case IH Services into one unique comprehensive package.

© 2026 All Rights Reserved

Interested in one of our Case IH machines? Request a personalized quote and we’ll get back to you with all the details you need to power up your next project!